English

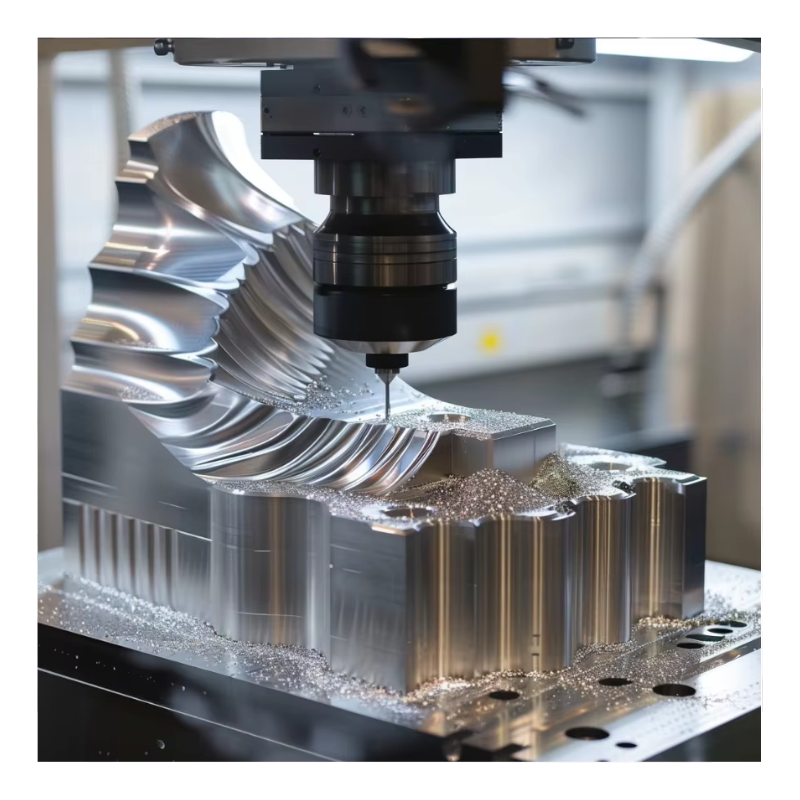

Precision, Consistency, and Trust in Special Material Machining

Writer:admin Time:2026-01-10 02:03 Browse:℃

China CNC factory specializing in titanium, nickel, and superalloy parts. Ensuring precision, consistency, and trust for global B2B clients.

In modern manufacturing, titanium alloys, nickel-based superalloys, and other high-performance materials are widely used in aerospace, energy, medical devices, and high-end industrial applications. These materials offer exceptional strength-to-weight ratios, corrosion resistance, and high-temperature stability, but they also present significant machining challenges. High material costs, rapid tool wear, and strict precision requirements make production demanding.

China-based CNC factories, such as those highlighted on EadeTech, have emerged as global leaders in this field, offering advanced machining, stringent quality control, and reliable B2B service. This article explores the technical, operational, and economic aspects of machining these special materials, providing real-world insights and data.

1. Why Special Material Machining Is Challenging

Titanium alloys, nickel-based alloys, and other high-performance materials are notoriously difficult to machine due to their intrinsic properties:

1.1 Low Thermal Conductivity and High Strength

For example, Ti-6Al-4V (TC4) has a thermal conductivity of 6.7–7.5 W/m·K, compared to aluminum alloys (~130 W/m·K) and steel (~44.5 W/m·K). Low thermal conductivity causes heat to concentrate at the cutting edge, accelerating tool wear and creating localized thermal expansion, which can lead to part distortion (Zenith In MFG, EadeTech).

1.2 High Elastic Modulus and Springback

TC4’s elastic modulus is ≈113.8 GPa, significantly higher than most steels and aluminum alloys. This increases the likelihood of springback in thin-wall components, making vibration control and fixture rigidity crucial (Neway Machining, EadeTech).

1.3 Rapid Tool Wear

Titanium and nickel-based alloys can reduce tool life by 3–5 times compared to standard steel. High cutting forces and abrasive particles accelerate wear, increasing operational cost and maintenance frequency (Renjie Precision, EadeTech).

1.4 Complex Geometry & Tight Tolerances

Many aerospace and industrial components require thin walls, internal channels, or complex 3D features with tolerances as tight as ±0.01 mm. Achieving such precision demands multi-axis CNC machines, optimized tool paths, and precise fixture design.

2. CNC Parameters and Material Performance

Industry data provide guidance for safe and efficient machining of titanium alloys, particularly TC4.

Table 1: Recommended CNC Parameters for Ti-6Al-4V Machining

| Operation | Cutting Speed (m/min) | Feed Rate | Depth of Cut | Notes |

|---|---|---|---|---|

| Rough Milling | 30–60 | 0.10–0.25 mm/tooth | 1.5–3.0 mm | TiAlN-coated tools, high-pressure coolant required |

| Finish Milling | 60–100 | 0.04–0.08 mm/tooth | 0.1–0.5 mm | Achieve smooth surface finish |

| Turning | 50–80 | 0.10–0.20 mm/rev | 1.0–2.0 mm | Positive rake angle, rigid fixturing needed |

| Drilling | 20–40 | 0.05–0.15 mm/rev | — | Monitor cutting temperature carefully |

Source: Industry CNC manuals and factory data (JLYPT, EadeTech)

Titanium requires lower cutting speeds and careful cooling compared to aluminum or steel, emphasizing process control to maintain surface quality and tool life.

3. Cost Structure of Special Material Machining

Material cost, tool consumption, machine time, fixturing, labor, and inspection contribute to total cost. For example:

Table 2: CNC Machining Cost Comparison

| Material | Raw Material Price ($/lb) | CNC Cost ($/hr) | Machining Difficulty | Overall Cost Ratio |

|---|---|---|---|---|

| Aluminum 6061 | $2–3 | $50–80 | Low | 1.0× |

| Stainless Steel 304 | $4–6 | $60–100 | Medium | 1.5× |

| Titanium Ti-6Al-4V | $25–35 | $100–150 | High | 4.5–6× |

Insight: Titanium alloy machining involves significantly higher material and process costs (EadeTech).

4. Quality Assurance and Process Control

High-value clients prioritize precision and consistency. Best-in-class Chinese CNC factories implement:

Tool selection and pre-checks: Coated carbide or PCD tools matched to material (EadeTech)

Multi-axis CNC with optimized toolpaths: 5-axis machining reduces fixture setup and errors

Real-time monitoring: Sensors and cameras track cutting forces and vibrations

Dimensional inspection: CMM, surface roughness, and profile measurements

Batch consistency: Documentation and traceability in accordance with ISO9001 and AS9100 standards

5. Case Study: Ultra-Thin Titanium Parts

For 2 mm wall thickness titanium components with ±0.01 mm tolerance:

Key Strategies

High-rigidity Fixtures: Minimize vibration during cutting

Segmented Light Cuts: Reduce thermal accumulation

High-pressure Coolant: Maintain stable part temperature

CNC Simulation Verification: Ensure toolpaths avoid deformation

These steps require experienced engineers and precise machine calibration, increasing both processing time and cost. More examples can be found on EadeTech.

6. Nickel-Based Superalloys

Nickel-based alloys like Inconel 718 are essential for aerospace turbines and energy equipment:

High cutting temperatures and stress lead to rapid tool wear

Small parameter deviations cause surface defects or microstructural damage

Specialized coatings, rigid tooling, and optimized feeds are mandatory (EadeTech)

Table 3: Thermal and Mechanical Properties of Difficult-to-Machine Materials

| Material | Thermal Conductivity (W/m·K) | Elastic Modulus (GPa) | Machining Difficulty |

|---|---|---|---|

| Aluminum 6061 | ~130 | 68.9 | Low |

| Titanium Ti-6Al-4V | 6.7 | 113.8 | High |

| Inconel 718 | 11 | 205 | Very High |

7. Consistency and Trust in B2B Manufacturing

B2B customers care about delivery reliability, process transparency, and traceable quality. Leading factories offer:

Detailed Process Route Cards

Tool and machine usage records

Inspection reports including CMM and material certificates

Long-term partnership terms with MOQ and stock management

These practices foster trust, essential for repeat business, as highlighted by EadeTech.

8. Innovation: Additive and Hybrid Manufacturing

Additive manufacturing techniques like Laser Metal Deposition (LMD) / Directed Energy Deposition (DED) allow complex shapes and reduce material waste. Hybrid approaches combine additive processes with precision CNC finishing, improving efficiency and precision (EadeTech).

Table 4: Additive vs CNC Machining Efficiency

| Process | Material Utilization | Lead Time | Precision | Typical Applications |

|---|---|---|---|---|

| CNC Machining | 60–70% | Medium | ±0.01 mm | Thin-wall parts, aerospace, prototypes |

| LMD/DED | 90–95% | Fast | ±0.05 mm | Hollow structures, large components |

| Hybrid CNC + LMD | 85–90% | Medium | ±0.01 mm | Complex aerospace parts, high-value components |

9. Conclusion: Precision, Consistency, and Trust

Machining special materials demands mastery of physics, tooling, CNC technology, and process control. The combination of:

Precision: Optimized parameters, simulation, high-quality equipment

Consistency: Standardized processes, monitoring, and inspection

Trust: Transparency, traceability, and certified quality

…forms the foundation of China-based CNC factories’ competitiveness in the global market. Clients worldwide rely on these capabilities for titanium, nickel, and superalloy parts, knowing that high-quality, reliable manufacturing is achievable while maintaining efficiency and cost-effectiveness.

More examples of advanced precision machining can be explored at EadeTech.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.