About us

Eadetech is a full-service global metal machining manufacturer in China, providing precision CNC machining, traditional machining, EDM, engraving, grinding, and a wide range of post-processing and surface finishing services. Serving customers worldwide, we specialize in producing high-quality metal components for industries including automotive, electronics, robotics, industrial equipment, and medical devices.

Our mission is to deliver cost-effective, high-precision metal parts that meet the exact specifications of engineers and procurement professionals while offering rapid prototyping, low-volume production, and reliable factory-direct shipping worldwide. By combining advanced manufacturing technologies with rigorous quality control, we help businesses accelerate their product development and maintain competitive advantages in their markets.

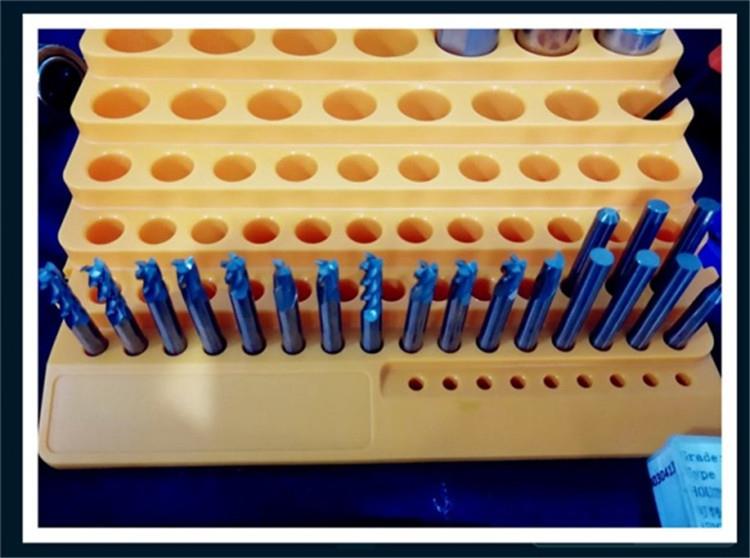

Our Expertise in Machining

At Eadetech, we provide a comprehensive suite of metal machining services, covering both CNC and traditional machining. Our expertise includes:

CNC Machining: Milling, turning, boring, drilling, 3–5 axis machining for complex parts.

Electrical Discharge Machining (EDM): High-precision wire EDM and sinker EDM for intricate geometries.

Metal Engraving & Fine Machining: Precision engraving and sculpting of metal surfaces for functional and aesthetic purposes.

Grinding & Surface Finishing: Cylindrical and surface grinding, planing, broaching, and polishing for smooth finishes and accurate tolerances.

Other Traditional Machining: Planing, drilling, broaching, and other specialized mechanical processes.

Our capabilities extend to tight tolerances up to ±0.01mm, ensuring components meet the most demanding technical requirements. We handle both single prototypes and low-volume production runs, helping clients reduce time-to-market and manufacturing costs.

Materials We Work With

Eadetech machines a wide variety of metals to suit different industry needs, including:

Aluminum (6061, 7075)

Stainless Steel (304, 316)

Brass

Titanium

Carbon Steel

Other Alloys

We also provide guidance on material selection and engineering design for manufacturability (DFM) to optimize performance and reduce production challenges.

Advanced Post-Processing & Surface Finishing

In addition to machining, Eadetech offers a comprehensive range of surface finishing services, ensuring your parts are ready for immediate assembly or sale. Our capabilities include:

Anodizing for aluminum parts.

Electroplating: Nickel, chrome, gold, silver, and alloy plating.

Passivation and Phosphating for stainless steel.

Powder Coating, Spray Painting, Dip Coating, UV Spraying for corrosion resistance and aesthetics.

Thermal Spraying & Plasma Coating: PEO/MAO, hot-dip galvanizing, plasma spraying.

Laser Engraving & Surface Strengthening: Marking, engraving, and hardening for durability.

Chemical Etching & Electroforming: Precise surface modifications and metal replication.

Nano Coatings & Anti-Fingerprint Coatings for functional protection.

Resin Casting with Metal & Special Treatments: Custom solutions for prototypes or decorative parts.

Our wide post-processing capabilities allow clients to complete both machining and finishing in a single factory, saving time, cost, and logistics challenges.

Factory-Direct Advantage

By working with Eadetech, customers benefit from our factory-direct model, which offers:

Competitive pricing without middlemen.

Consistent quality across prototypes and low-volume production.

Fast turnaround: prototypes in 5–7 days, small batches in 10–15 days.

Global shipping with reliable delivery.

Direct communication with engineers for DFM feedback and production guidance.

Owning and operating all equipment in-house allows us to maintain full control over quality, precision, and delivery schedules.

Quality Assurance

Quality is central to Eadetech’s operations. Our ISO-certified factory ensures that every part is inspected thoroughly at each stage. Our practices include:

Dimensional inspection using CMM, calipers, micrometers, and other precision instruments.

Material verification to ensure correct specifications.

Process traceability for every order.

In-process inspections to catch deviations early.

Final inspection before shipment to guarantee compliance with client specifications.

This quality system ensures that every component meets international standards for precision and reliability.

Our Process

Eadetech has streamlined a process that makes global manufacturing simple and reliable:

Request a Quote – Upload CAD files or drawings.

Engineering Review – Our team checks manufacturability and provides suggestions.

Prototype / Production – Machining using CNC, EDM, or traditional methods.

Surface Finishing – Apply anodizing, plating, coatings, or other treatments as required.

Quality Inspection – Dimensional and surface checks to ensure compliance.

Packaging & Worldwide Shipping – Safe, on-time delivery to your facility anywhere in the world.

Industries We Serve

We supply precision metal components to a wide range of industries:

Automotive & Transportation: Engine components, chassis brackets, and structural parts.

Industrial Equipment: Gears, housings, frames, and functional assemblies.

Medical Devices (Non-Implant): Diagnostic equipment, lab instruments, and medical machinery parts.

Electronics & Robotics: Heat sinks, brackets, housings, and mechanical components.

Consumer Products & Decorative Items: Engraved or coated metal components for aesthetic and functional purposes.

No matter the application, Eadetech’s precision machining and finishing expertise ensures performance, durability, and quality.

Why Choose Eadetech?

Global CNC & Metal Machining Manufacturer in China

Comprehensive Services: CNC, EDM, engraving, grinding, milling, turning, boring, drilling, and post-processing.

Rapid Prototyping & Low-Volume Production – accelerate development and reduce inventory risk.

Tight Tolerances & High Precision – ±0.01mm for demanding applications.

Factory-Direct Efficiency – ISO-certified quality, controlled processes, reliable worldwide shipping.

Engineering Support – DFM review, CAD consultation, and production guidance.

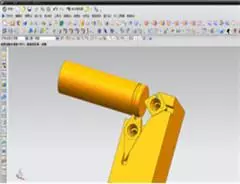

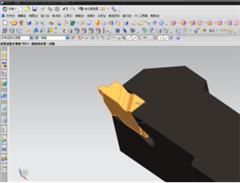

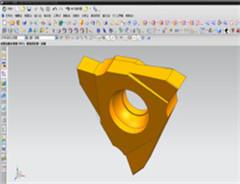

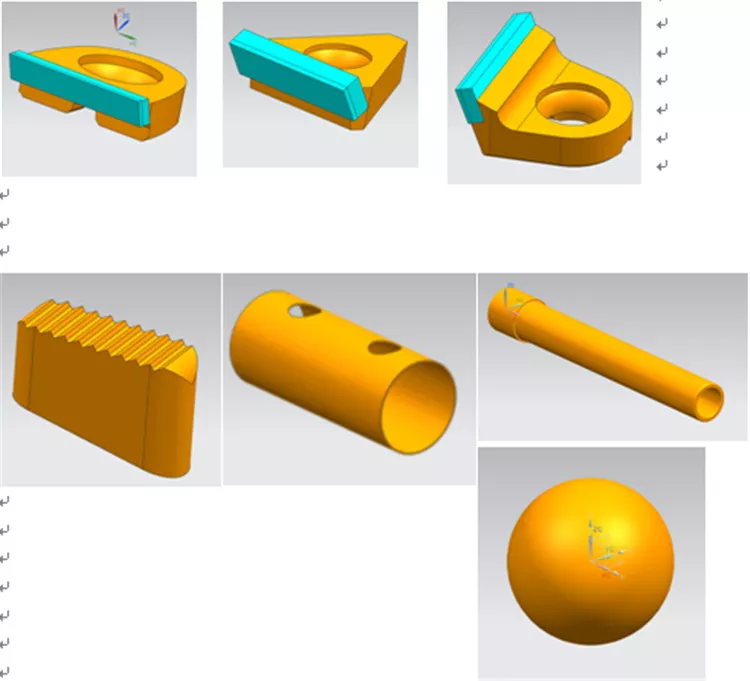

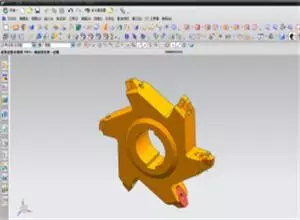

※ What we can do?

Provide inserts designing, inserts manufacturing, tooling designing, tooling manufacturing and other carbide products;

Our engineers will provide you with a very clear conception to make parts machining become easy and reasonable. And we can consequently guarantee the tools quality and improve the efficiency.

Parts drawing is key fact for making good inserts, nowadays everyone knows this point, but not everyone know how to design the good inserts drawing, one key is to keep data update, easy to find out, easy to track, every changing version needs to be kept in case some time we need track some data from old version. And communicating with customers about application are very important.

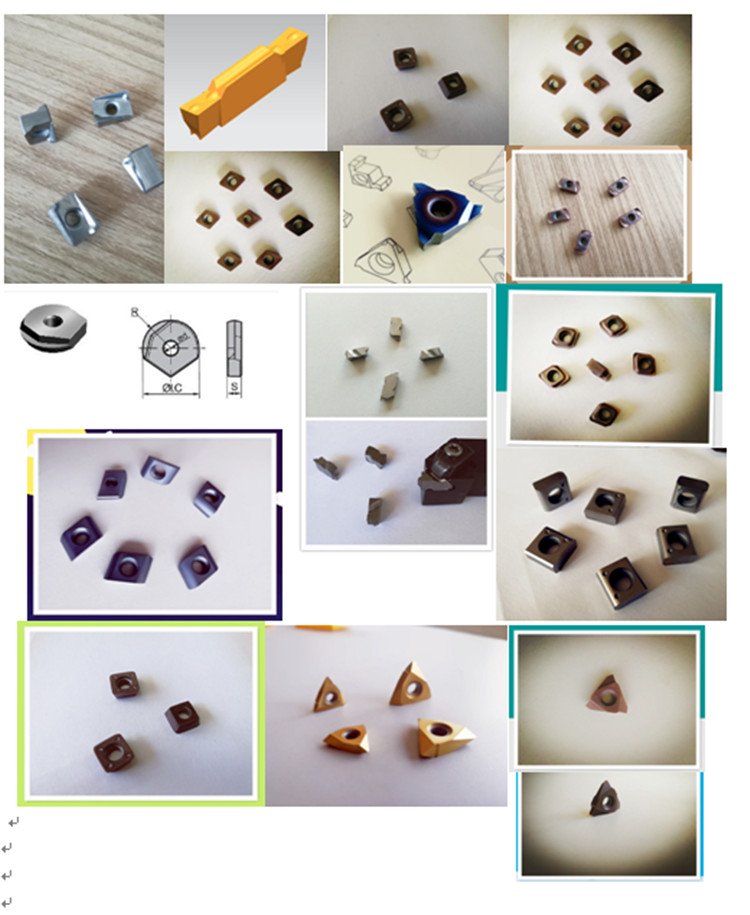

※ What’s products we can provide?

Parting& Grooving inserts, threading inserts, profile inserts, turning inserts, face milling inserts, square shoulder milling inserts, non-standard inserts, shims, woodworking inserts, etc.

※ Our mission

Our mission is “to provide value-added manufacturing services with creative engineering for customers with complex needs.” By doing so we can help our customers manufacture world class products and quickly bring them to market.

Contact Eadetech

Ready to start your project? Eadetech is your trusted global CNC and metal machining partner. We handle prototypes, small batch production, and high-precision components in aluminum, stainless steel, brass, titanium, and carbon steel.

Request a Quote – Get a response within 24 hours.

Upload CAD Files Directly – Streamlined communication and fast turnaround.

Reliable Worldwide Delivery – Factory-direct shipping from China to your facility.

Let Eadetech help bring your ideas to life with precision, speed, and cost-efficiency.、

、

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Panyu District, Guangzhou, Guangdong Province, China