English

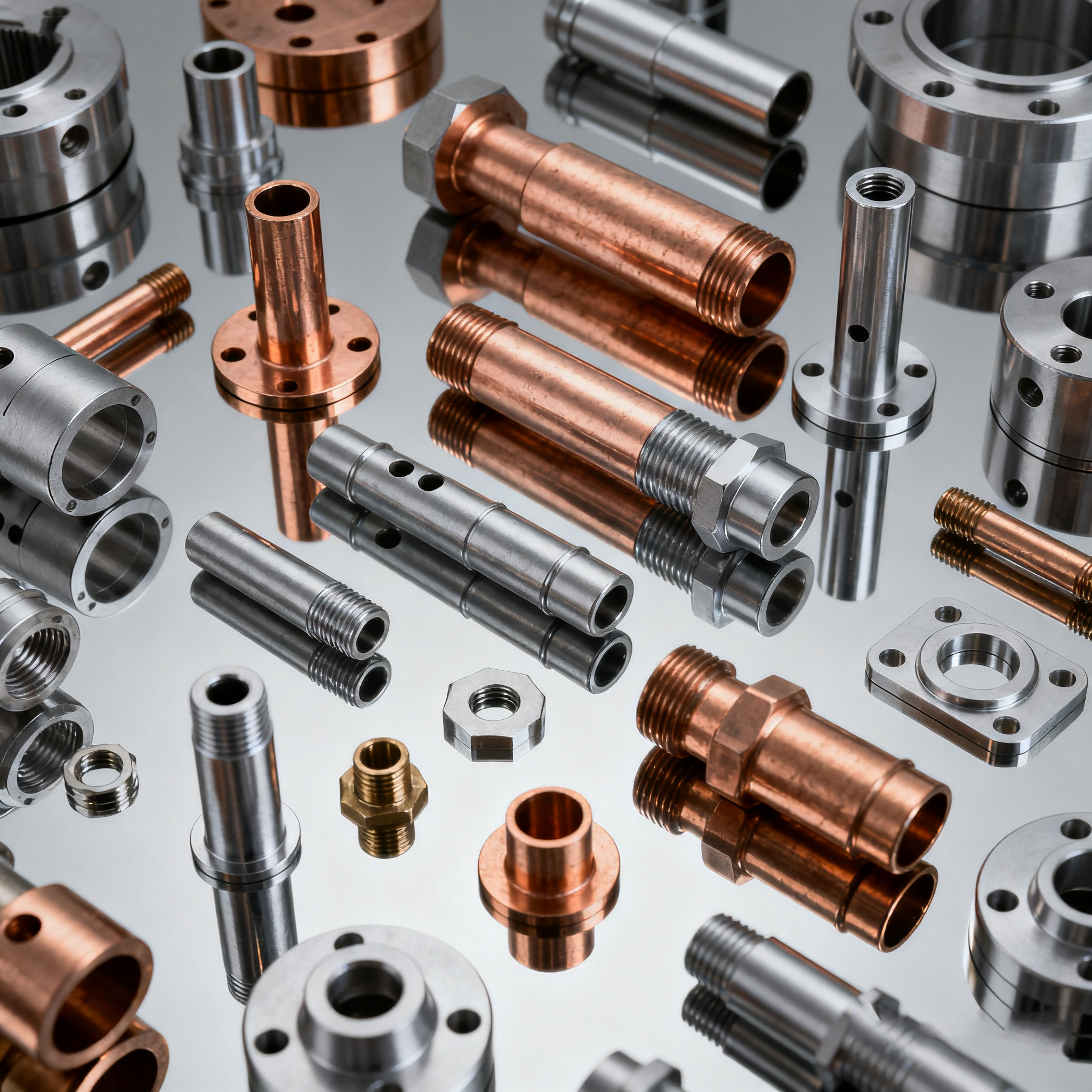

From Prototype to Production: Special Material CNC Machining

Writer:admin Time:2026-01-10 02:03 Browse:℃

Why trusted CNC machining partners matter — from early concept prototypes to high‑volume production runs in titanium, nickel, and superalloy components.

Manufacturing components from advanced materials such as titanium, nickel alloys, and superalloys has become a cornerstone of high‑performance industries including aerospace, automotive, medical devices, and energy systems. These materials provide exceptional strength, corrosion resistance, lightweight performance, and durability — but they also require sophisticated machining strategies that differ significantly from traditional metals like aluminum or mild steel.

Whether you are developing a new part prototype or scaling to batch production, understanding the full machining lifecycle for these difficult‑to‑machine materials is essential. In this article, we explore technical realities, process planning, quality systems, economic factors, and practical workflows that define successful machining — with real data tables, and references to industry insights such as those on EadeTech.

1. Why Special Materials Require Unique CNC Machining Expertise

Before we examine prototyping or production processes, it’s important to grasp why advanced alloys challenge conventional machining:

1.1 Intrinsic Material Properties

Advanced alloys such as Ti‑6Al‑4V (Titanium) or Inconel 718 (Nickel Superalloy) have mechanical and thermal properties that make them difficult to machine:

Table 1: Key Properties Impacting Machinability

| Material | Thermal Conductivity (W/m•K) | Elastic Modulus (GPa) | Hardness (HRC) | Machinability |

|---|---|---|---|---|

| Aluminum 6061 | ~130 | ~69 | ~55 | Easy |

| Stainless Steel 304 | ~16 | ~193 | ~70 | Medium |

| Ti‑6Al‑4V | ~7 | ~113.8 | ~36‑38 | Difficult |

| Inconel 718 | ~11 | ~205 | ~45‑48 | Very Difficult |

These values explain why titanium and nickel superalloys generate high cutting heat, cause tool wear, and are susceptible to work‑hardening — all challenges that require expert tool selection and machining strategies (details and case studies available on EadeTech).

2. Prototyping Phase: Setting the Foundation

Prototyping is more than a cost checkpoint; it’s where critical design decisions influence manufacturability, performance, and scaling feasibility.

2.1 Design for Manufacturability (DFM)

In prototyping, engineers must consider:

Wall thickness limits

Internal cavities or deep bores

Thin features prone to vibration

Precision surface requirements

For example, thin wall sections (< 2 mm) often require stiff fixtures and controlled feed rates to prevent distortion. This is especially true in titanium prototypes, where elastic recovery can be significant.

2.2 Choosing the Right Material Version

Even within a single alloy family, multiple grades exist. For instance, Ti‑6Al‑4V ELI is preferred in medical applications due to improved ductility, while standard Ti‑6Al‑4V may suffice for aerospace structural parts.

2.3 CNC Prototype vs. Additive Processes

Often, early prototypes combine:

Additive manufacturing for rough shape

CNC finish machining for precision surfaces

Hybrid workflows — increasingly documented in industry resources like EadeTech’s technology section — accelerate iterative testing while minimizing material waste.

3. CNC Machining Parameters: Early Decisions Matter

One of the most critical elements in transitioning from prototype to production is understanding and optimizing cutting parameters. These affect surface quality, tool life, and cycle time.

Table 2: Representative Machining Parameters for Titanium & Superalloys

| Material | Cutting Speed (m/min) | Feed (mm/tooth) | Depth of Cut (mm) | Coolant Strategy |

|---|---|---|---|---|

| Ti‑6Al‑4V Rough | 25‑45 | 0.10‑0.20 | 1.5‑3.0 | High‑pressure flood |

| Ti‑6Al‑4V Finish | 50‑90 | 0.04‑0.08 | 0.1‑0.3 | Mist + flood |

| Inconel 718 Rough | 20‑35 | 0.08‑0.15 | 1.2‑2.5 | Flood + high pressure |

| Inconel 718 Finish | 40‑70 | 0.03‑0.07 | 0.1‑0.5 | Flood + air mist |

These parameter ranges are widely referenced by machining experts and serve as starting points that seasoned CNC partners refine through trial runs — as discussed in technical references on EadeTech.

4. Quality Control and Measurement Systems

As prototypes evolve into production parts, precision tolerances and repeatability are non‑negotiable. Reliable vendors implement rigorous quality systems.

4.1 Inspection Tools and Standards

Coordinate Measuring Machines (CMM)

Surface Roughness Profilers

Digital Calipers and Micrometers

Non‑Destructive Testing (NDT)

First Article Inspection (FAI) reports

Quality systems typically align with standards such as ISO 9001, AS9100 (aerospace), and sometimes ISO 13485 for medical devices.

4.2 Ensuring Repeatability

Production machining introduces variation risk — machine wear, tool changes, and environmental factors can alter outcomes. Continuous calibration and in‑process monitoring mitigate these risks.

5. Cost Structures: Prototype vs. Volume Production

Understanding how costs evolve as you scale helps stakeholders plan budgets and pricing strategies.

Table 3: Cost Dynamics — Prototype vs. Production

| Cost Component | Prototype | Small Batch | Mass Production |

|---|---|---|---|

| Material | High | Moderate | Economies of scale |

| Tooling | High | Moderate | Lower per piece |

| CNC Setup | Moderate | Lower | Lowest per unit |

| Quality Inspection | High | Moderate | Standardized |

| Total Cost (relative) | 1.0× | 0.7× | 0.4× |

As production volume increases, the per‑part cost drops significantly due to amortization of setup and tooling. Early prototyping invests in precision fixture design and toolpath tuning, but once established, production flows significantly reduce per‑unit costs.

6. Supply Chain Integration: From Prototype Approval to Full Production

Once prototypes are validated, the transition to production requires structured supply chain planning.

6.1 Bills of Materials (BOM) and Work Orders

Work orders derived from prototyping must accurately represent:

Material specs (e.g., Ti‑6Al‑4V heat code traceability)

Tolerance requirements

Surface finish & coating expectations

Inspection checkpoints

Many CNC partners documented on EadeTech emphasize BOM accuracy as a cornerstone of consistent quality.

6.2 Material Procurement and Inventory

Managing long‑lead materials (e.g., titanium bars, Inconel blanks) is essential. Production planning often creates buffer inventory strategies to prevent bottlenecks.

6.3 Scheduling and Capacity Planning

Reliable machine shops use software tools for capacity planning, ensuring bottleneck machines (e.g., 5‑axis centers for complex geometries) are prioritized and scheduled efficiently.

7. Production Challenges and Solutions

Even a well‑planned transition can face hurdles. Here’s how trusted machining partners address common production issues:

7.1 Machine Wear and Tool Degradation

Advanced alloys accelerate tool wear. To mitigate:

Predictive tool wear models

Scheduled tool replacements

Adaptive feed adjustment

Machining partners profiled on EadeTech often document real‑time monitoring systems that track force, vibration, and tool life.

7.2 Thermal Deformation

Long runs generate heat, affecting dimensional stability. Effective cooling strategies and machine calibration counteract drift.

7.3 Process Variation

Part families with similar features benefit from standardized machining templates, reducing process variance.

8. Automation and Industry 4.0 Integration

Modern CNC production increasingly incorporates automation tools, including:

Robotic load/unload systems

Real‑time SPC (Statistical Process Control)

Automated inspection arms

ERP/MES system integration

These systems improve throughput and consistency — especially important in high‑precision manufacturing of aerospace or medical device parts.

9. Surface Finishing & Secondary Operations

After primary machining, many parts require secondary processes:

Anodizing (for corrosion resistance)

Passivation (especially for stainless steels)

Grinding / Polishing

Thread rolling or tapping

Surface finish requirements often match industry standards such as Ra ≤ 0.8 µm for aerospace components. Finishing workflows are documented in machining process libraries such as those referenced on EadeTech.

10. Real‑World Material Comparison: Machinability Data

Table 4: Relative Tool Life by Material (Example Data)

| Material | Coated Carbide Tool Life (benchmark = 1.0) | Notes |

|---|---|---|

| Aluminum 6061 | 1.0 | Baseline machinability |

| Stainless Steel 304 | 0.8 | Moderate wear |

| Titanium Ti‑6Al‑4V | 0.3 | High wear |

| Inconel 718 | 0.25 | Very high wear |

This simplified table highlights tool life differences between common and exotic materials — information CNC partners evaluate when planning production (see similar data on EadeTech).

11. Quality Performance Metrics at Scale

At production volume, reliability includes:

Yield rate (% of parts within tolerance)

Scrap reduction trends

On‑time delivery percentage

Customer defect feedback rate

Table 5: Sample Production Quality Metrics

| Metric | Goal | Typical High‑Performing Shop |

|---|---|---|

| Yield Rate | ≥ 95% | 99% |

| Scrap Rate | ≤ 5% | 1–2% |

| On‑Time Delivery | ≥ 90% | 97% |

| Customer Complaints | ≤ 2% | < 1% |

These metrics reflect world‑class machining operations that combine process control with rigorous inspection — insights often discussed among machining professionals and referenced on EadeTech.

12. Case Study: Aerospace Bracket From Prototype to Production

To illustrate the full lifecycle:

Prototype Phase:

Initial runs focus on validating geometry and surface finish.

Toolpaths are iteratively tuned to manage titanium’s low thermal conductivity.

Measurement data guides design adjustments.

Pilot Production:

Small batch runs verify repeatability.

Fixturing and inspection protocols are standardized.

Cost per part begins to converge.

Full Production:

Automated loading and SPC monitoring implemented.

Just‑in‑time material management improves cycle flow.

Yield stabilizes above 99%.

This progression demonstrates how a machining partner transitions from iterative prototyping to confident, high‑quality production output.

13. Choosing a Reliable CNC Machining Partner

When selecting a partner for specialized machining, B2B buyers should prioritize:

Material expertise and real case experience (e.g., titanium, Inconel)

Multi‑axis machining capability (3, 4, and 5‑axis)

Documentation & traceability standards

Process transparency and communication

Quality systems (ISO/AS certification)

Scalability from prototype to mass production

Resources like EadeTech provide detailed insights into what separates reliable machining partners from general machine shops — a valuable reference for procurement engineers.

14. Final Thoughts: Integration, Trust, and Long‑Term Partnership

From initial concept to high‑volume production, the journey of special material machining demands technical expertise, repeatable processes, and robust quality systems. A reliable CNC partner reduces risk, drives cost predictability, and ensures performance — particularly in demanding sectors like aerospace and medical devices where failures are not an option.

For deeper case studies, machining strategies, and production optimization insights, explore the authoritative resources available at https://www.eadetech.com.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.