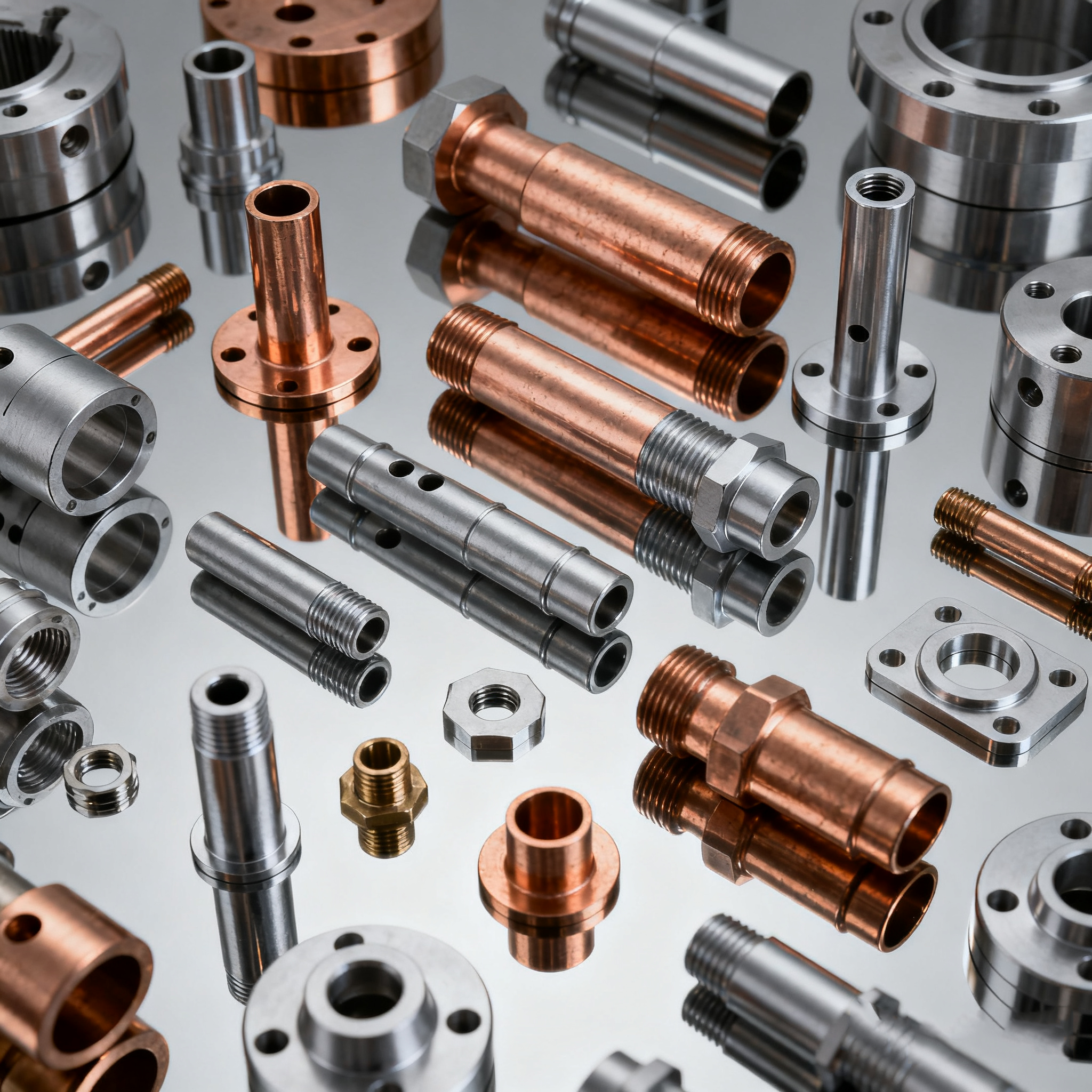

Titanium CNC Turning Parts

Titanium Welding and CNC Machining for Industrial Equipment and Structural Assemblies

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-06-03 00:00

- Price: 0

CNC titanium milling for structural plates, ribs, and connection features

Titanium lathe turning for cylindrical joints, sleeves, and alignment components

Drilling and finishing operations for bolt holes and assembly interfaces

Titanium milling to refine mounting surfaces and flanges

Titanium turning to restore concentricity in welded cylindrical features

Finishing passes to meet tight tolerance requirements

Visual inspection of weld beads and heat-affected zones

CMM dimensional inspection of machined features

Ultrasonic testing for internal weld defects

Metallographic analysis for material validation

Background: Combining Titanium Welding and Machining in Industrial Manufacturing

Background: Combining Titanium Welding and Machining in Industrial Manufacturing

In industrial manufacturing, many titanium components are not produced solely through machining. Instead, welding and machining are often combined to create large structural assemblies, pressure-resistant frames, and complex equipment parts. Titanium welding, when properly executed, allows manufacturers to join multiple machined components into robust assemblies while maintaining corrosion resistance and mechanical strength.

In this case, the customer was an industrial equipment manufacturer producing titanium structural frames and fluid-handling assemblies used in chemical processing and advanced manufacturing systems. The project required close integration between titanium CNC machining and titanium welding processes, with strict control over distortion, strength, and dimensional accuracy.

Titanium Materials and Weldability Considerations

The project involved titanium alloys commonly used in industrial applications where corrosion resistance and structural strength are critical. While titanium offers excellent performance, welding titanium presents unique challenges due to its high reactivity with oxygen, nitrogen, and hydrogen at elevated temperatures.

The machinability of titanium alloys and their weldability must be considered together. Improper sequencing of machining and welding can introduce residual stress, distortion, or surface contamination that compromises final part quality.

To manage these risks, welding procedures were carefully controlled, and machining allowances were designed to compensate for potential distortion during welding.

CNC Machining of Titanium Components Before Welding

Before welding, individual components were produced through CNC titanium machining to achieve precise geometry and controlled interfaces.

Key machining processes included:

Machining strategies focused on maintaining consistent wall thickness and minimizing sharp internal corners to reduce stress concentration after welding.

All machined titanium parts were inspected prior to welding to ensure dimensional accuracy and surface cleanliness.

TIG Welding Titanium for Precision Assemblies

TIG welding titanium was the primary joining method used in this project due to its precision, cleanliness, and control. TIG welder titanium processes allowed for stable arc control and minimal contamination, which is essential when welding titanium alloys.

Weld areas were shielded with high-purity inert gas to prevent oxidation. Weld parameters were optimized to achieve full penetration while minimizing heat input and distortion.

After welding, critical weld zones were inspected to ensure proper fusion and structural integrity before secondary machining operations.

MIG Welding Titanium for Structural Strength

For thicker sections and non-critical cosmetic areas, MIG welder titanium processes were applied to improve productivity while maintaining adequate strength.

Titan MIG welder systems were used where higher deposition rates were required. Although MIG welding titanium is less common than TIG, it was suitable for selected structural components in this case where post-weld machining was planned.

Careful control of shielding gas coverage and welding environment ensured weld quality and consistency across all titanium welder parts.

Post-Weld Machining and Dimensional Control

After welding, assemblies underwent secondary CNC machining to restore precision features affected by thermal distortion.

Post-weld operations included:

Critical dimensions were controlled within ±0.01 mm after final machining. This ensured proper fit and functionality of the welded titanium assemblies in the customer’s industrial equipment.

Heat Treatment and Stress Management

Heat treatment was applied selectively to relieve residual stresses introduced during welding and machining. Solution and aging processes were used on specific titanium alloys to stabilize mechanical properties.

Stress relief was particularly important for welded assemblies with long structural spans. Metallographic analysis was conducted to verify that welding and heat treatment did not negatively affect microstructure or material integrity.

Inspection and Quality Assurance

Titanium welding and machining projects require comprehensive inspection to ensure both weld quality and dimensional accuracy.

Inspection procedures included:

All production was carried out under ISO9001:2015 and IATF16949 certified quality systems, ensuring traceability and repeatability.

OEM Manufacturing and Engineering Support

This project was completed under an OEM model. The customer provided assembly drawings and performance requirements, while engineering support focused on optimizing weld joint design and machining sequences.

CAD and CAM systems such as SolidWorks, UG, and CATIA were used to simulate welding distortion and plan post-weld machining operations. Supported drawing formats included STEP, DWG, DXF, IGS, STL, and PDF.

Free samples were produced during the validation stage to allow functional testing and assembly verification.

Industrial Applications of Titanium Welding and Machining

The combination of titanium welding and CNC machining is widely used across industrial sectors. Similar processes are applied in energy systems, chemical processing equipment, robotics frames, and advanced manufacturing machinery.

The ability to integrate TIG welding titanium, MIG welding titanium, and precision machining enables manufacturers to produce complex, high-strength titanium assemblies that cannot be achieved through machining alone.

Conclusion

This case demonstrates how titanium welding and CNC machining can be effectively combined to produce high-quality industrial assemblies. By controlling weld environment, machining sequences, and post-weld finishing, manufacturers can overcome the challenges associated with titanium machinability and weldability.

Through TIG welder titanium processes, MIG welder titanium applications, and precision machining of titanium alloys, industrial customers gain access to durable, corrosion-resistant, and dimensionally accurate titanium assemblies.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.