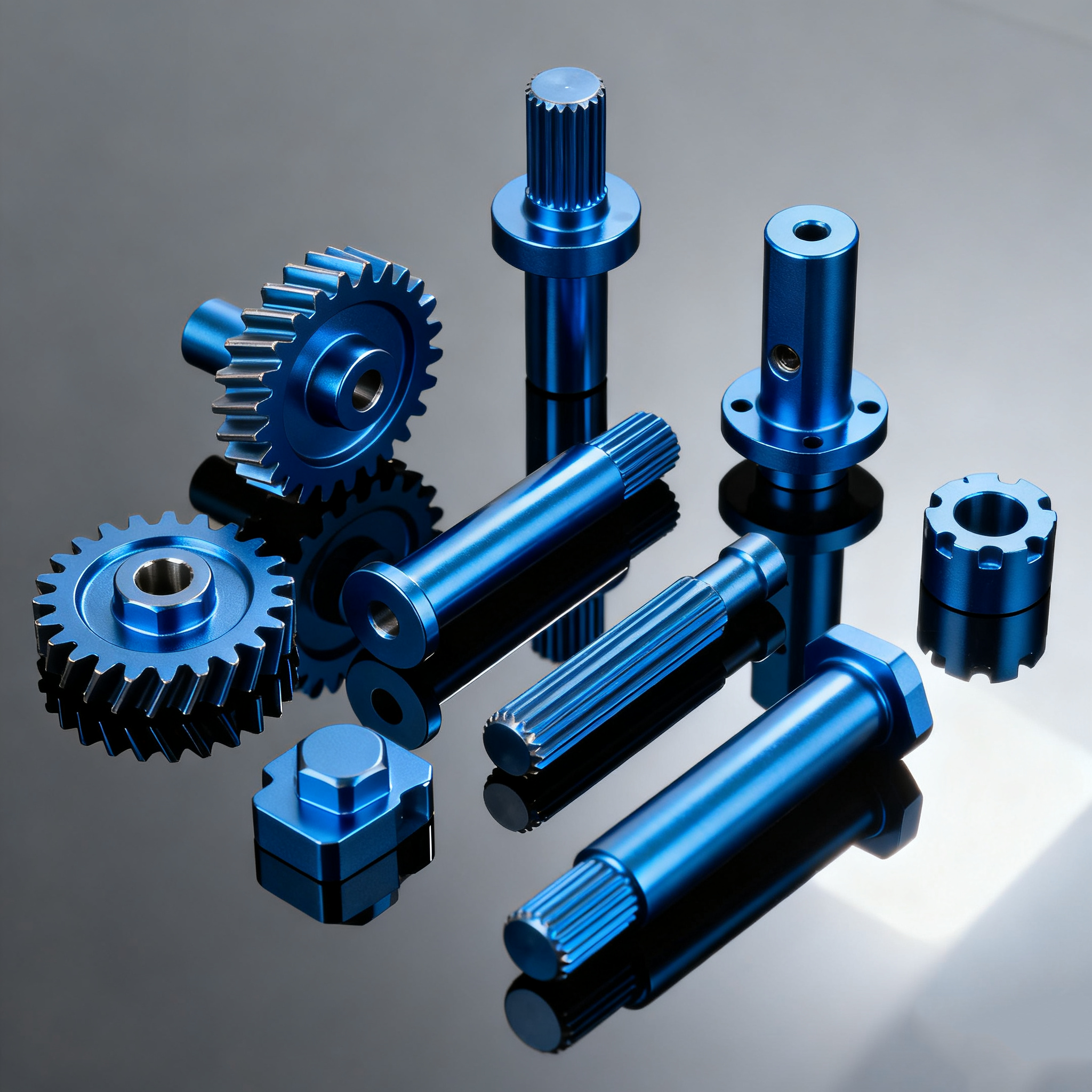

Titanium CNC Turning Parts

EDM and Wire EDM Titanium Machining for High-Precision Internal Features

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-06-17 00:00

- Price: 0

High dimensional accuracy for internal contours

Minimal mechanical stress on thin-walled features

Ability to achieve sharp internal corners

Stable repeatability for batch production

Deep internal pockets

Precision cavities with tight corner radii

Stress-sensitive titanium components

Accurate datum surfaces for EDM alignment

Efficient material removal for open areas

Reduced EDM processing time

CMM dimensional inspection

Metallographic analysis of EDM zones

Ultrasonic testing where applicable

100% visual inspection and gauge checks

Background: Why EDM Is Essential in Titanium Machining

Background: Why EDM Is Essential in Titanium Machining

Titanium CNC machining is highly effective for external profiles and open features, but certain geometries remain difficult or inefficient to produce using conventional cutting methods. Deep internal slots, sharp internal corners, micro cavities, and stress-sensitive features often require alternative machining processes. EDM titanium machining has become a critical solution for these challenges.

In this case, the customer was a precision equipment manufacturer producing titanium components with complex internal features used in aerospace tooling and advanced industrial systems. The project demanded extremely high dimensional accuracy, minimal mechanical stress, and stable repeatability across small production batches.

Titanium Material Behavior in EDM Processes

The machinability of titanium alloys differs significantly between conventional cutting and EDM processes. While titanium is difficult to cut due to heat concentration and tool wear, EDM titanium machining removes material through controlled electrical discharge, eliminating direct tool contact.

This non-contact process is particularly suitable for titanium alloys with high strength and low thermal conductivity. However, EDM introduces localized thermal effects that must be carefully managed to avoid recast layers, micro-cracks, or surface integrity issues.

To address this, EDM parameters were optimized for stable discharge energy, controlled flushing, and consistent spark gaps.

Wire EDM Titanium for Precision Profiles

Wire EDM titanium machining was the primary process used for this project’s most demanding features. Components included internal windows, narrow slots, and sharp-corner profiles that could not be produced by titanium milling alone.

Wire EDM titanium offered several advantages:

The process allowed complex profiles to be cut directly from solid titanium stock, reducing the need for multi-step machining and minimizing cumulative error.

Sinker EDM Titanium for Cavities and Micro Features

For enclosed cavities and blind internal features, sinker EDM titanium machining was applied. Custom electrodes were designed to match complex cavity geometries while maintaining controlled material removal.

Sinker EDM was especially effective for:

Electrode wear was closely monitored, and multiple finishing passes were used to achieve consistent surface quality and dimensional accuracy.

Integration with CNC Titanium Machining

EDM titanium machining was integrated with CNC titanium machining to produce complete parts. External features, mounting interfaces, and reference surfaces were machined using CNC titanium milling and titanium turning before EDM operations.

This hybrid approach ensured:

After EDM, final finishing passes were performed where necessary to meet tolerance and surface requirements.

Tolerance Control and Dimensional Accuracy

The components in this case required extremely tight tolerances due to their functional role in precision assemblies. Critical dimensions were controlled within ±0.01 mm across both CNC and EDM-machined features.

Dimensional verification was carried out using CMM inspection, supported by gauge measurement and 100% visual inspection. Special attention was given to EDM-affected zones to ensure dimensional stability and surface consistency.

Surface Integrity and Quality Considerations

Surface quality is a key concern in EDM titanium machining. Improper parameter selection can result in excessive recast layers or micro-cracking.

In this project, finishing EDM passes were applied to reduce surface roughness and improve surface integrity. Where required, light CNC finishing operations were used to remove recast layers from functional surfaces.

Metallographic analysis confirmed that EDM processing did not compromise the microstructure or performance of the titanium material.

Heat Treatment and Stress Relief

Heat treatment was applied selectively after EDM and CNC machining to relieve residual stresses and stabilize mechanical properties. Solution and aging processes were used for specific titanium alloys based on performance requirements.

Stress relief was particularly important for thin-walled parts produced through wire EDM titanium, where localized thermal effects could influence dimensional stability.

Inspection, Quality Control, and Certification

All EDM and CNC machining processes in this case were conducted under ISO9001:2015 and IATF16949 certified quality systems.

Inspection procedures included:

Complete inspection reports and material traceability documentation were provided with each production batch.

OEM Support and Engineering Collaboration

The project was executed under an OEM model, with the customer providing detailed drawings and functional specifications. Engineering collaboration focused on determining which features were best suited for EDM titanium machining versus CNC machining.

CAD and CAM tools such as SolidWorks, UG, and CATIA were used to simulate machining sequences and EDM electrode design. Supported drawing formats included STEP, DWG, DXF, IGS, STL, and PDF.

Free samples were provided during the validation phase to support functional testing and assembly trials.

Applications of EDM Titanium Machining

The EDM titanium machining strategies used in this case are widely applicable across industries requiring extreme precision. Aerospace tooling, robotics components, energy system parts, and advanced industrial equipment frequently rely on wire EDM titanium and sinker EDM titanium processes.

For titanium machining companies serving high-end markets, EDM capabilities are essential for expanding design possibilities and meeting demanding customer requirements.

Conclusion

This case demonstrates the critical role of EDM titanium machining in producing high-precision components with complex internal features. By combining wire EDM titanium, sinker EDM titanium, and CNC titanium machining, manufacturers can overcome the limitations of conventional cutting methods.

Through careful control of EDM parameters, inspection standards, and post-processing, precision machined titanium parts can meet the strictest functional and dimensional requirements.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.