Titanium CNC Turning Parts

Automotive Titanium CNC Machining for High-Performance Engine and Chassis Parts

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-05-22 00:00

- Price: 0

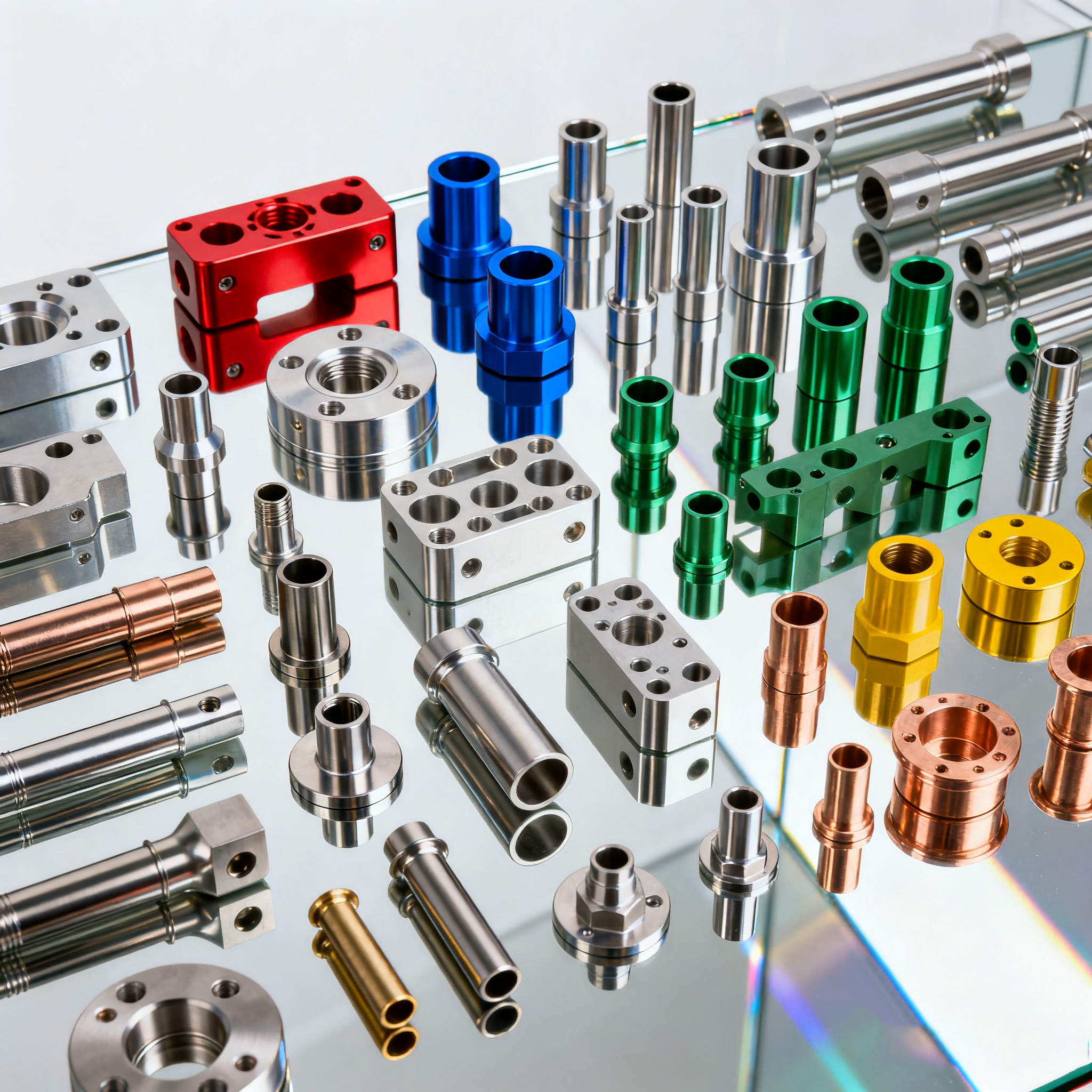

CNC titanium milling for brackets, suspension connectors, and structural supports

Titanium lathe turning for shafts, bushings, and cylindrical mounting interfaces

Waterjet titanium cutting for flat profiles and pre-shaped blanks

Secondary drilling and finishing operations for assembly features

CMM dimensional verification

100% visual inspection combined with gauge checks

Metallographic analysis for material validation

Batch traceability and process documentation

Background: Titanium Machining in High-Performance Automotive Applications

In the automotive industry, titanium machining is primarily associated with high-performance, motorsport, and premium vehicle segments. Compared to steel and aluminum, titanium offers a unique balance of high strength, low weight, corrosion resistance, and thermal stability. These properties make titanium especially suitable for performance-critical automotive components where durability and weight reduction directly affect speed, efficiency, and reliability.

In this case, the customer was a performance automotive parts manufacturer supplying engine and chassis components for sports cars and track-focused vehicles. The project involved custom titanium CNC machining for multiple parts used in exhaust systems, suspension linkages, and engine mounting assemblies.

The customer required consistent dimensional accuracy, reliable batch repeatability, and machining solutions capable of handling complex geometries while maintaining cost efficiency for small-to-medium production volumes.

Material Selection and Machinability of Titanium in Automotive Use

The project primarily utilized titanium alloys commonly applied in automotive performance parts. These alloys offer improved strength compared to commercially pure titanium, while maintaining good fatigue resistance under vibration and thermal cycling.

However, the machinability of titanium alloys poses challenges in automotive manufacturing environments that prioritize both speed and cost control. Titanium’s low thermal conductivity leads to concentrated heat at the cutting edge, increasing tool wear during titanium milling and titanium turning operations.

To address this, machining strategies focused on high speed machining titanium techniques with controlled spindle speeds, optimized feed rates, and the use of dedicated end mills for titanium. Toolpath optimization reduced cutting engagement and minimized heat buildup, improving surface quality and extending tool life.

CNC Machining Processes for Automotive Titanium Parts

This automotive case required a combination of CNC machining processes to meet functional and structural requirements across different components.

Key processes included:

Waterjet cutting titanium was used during the early-stage material preparation to reduce waste and avoid thermal distortion. This approach allowed near-net-shape blanks to be produced efficiently before CNC finishing operations.

All components were machined using CNC titanium machining centers to ensure consistency from prototype validation through production runs.

High Speed Machining and Cycle Time Optimization

Automotive manufacturing places greater emphasis on cycle time efficiency compared to aerospace or medical applications. In this project, high speed machining titanium was critical for balancing performance requirements with production cost targets.

Machining parameters were optimized through iterative testing, focusing on stable cutting conditions rather than maximum material removal rates. Adaptive toolpaths and constant engagement strategies were applied to reduce vibration and tool deflection.

Titanium milling operations were sequenced to minimize tool changes and repositioning, while titanium turning processes were optimized for continuous cutting to improve surface finish and dimensional stability.

These measures significantly reduced machining time while maintaining the tight tolerances required for performance automotive assemblies.

Tolerance Control and Functional Accuracy

Although automotive tolerances are generally less stringent than aerospace standards, high-performance components still require precise dimensional control to ensure proper fit and long-term reliability.

For this project, critical features were controlled within ±0.01 mm. Particular attention was paid to mating surfaces, bearing interfaces, and load-bearing geometries subjected to vibration and thermal expansion.

Dimensional inspection was carried out using CMM systems, supported by 100% visual inspection and gauge verification. This ensured that every machined titanium part met functional requirements before shipment.

Heat Treatment and Mechanical Stability

Heat treatment was applied selectively based on component function. For parts exposed to cyclic loads and high temperatures, solution and aging processes were used to enhance strength and fatigue resistance.

Stress relief was also applied after rough machining to reduce distortion during final finishing. This step was particularly important for long, slender titanium components produced through titanium lathe turning, where residual stress could affect straightness and concentricity.

Metallographic analysis confirmed that the heat treatment process maintained consistent microstructure and mechanical performance across production batches.

Surface Treatment for Automotive Environments

Surface treatment requirements in automotive applications vary depending on exposure conditions and aesthetic considerations.

In this case, brushing was applied to visible components to achieve a uniform surface texture. Anodizing was used on selected titanium parts to improve corrosion resistance and enhance visual differentiation in performance assemblies.

For certain auxiliary components, powder coating and zinc plating were applied where additional environmental protection was required. All surface treatments were selected to maintain compatibility with titanium material properties and automotive operating conditions.

Inspection, Quality Systems, and Certification

The production of automotive titanium components was supported by a structured quality management system compliant with ISO9001:2015 and IATF16949 standards.

Inspection methods included:

These inspection and quality control measures ensured consistent performance and repeatability, supporting the customer’s supply chain requirements for high-performance automotive parts.

OEM Support and Engineering Collaboration

The project was executed under an OEM model, with the customer providing detailed drawings and functional specifications. Engineering collaboration focused on optimizing part geometry for titanium machinability while preserving structural performance.

Design feedback included recommendations on fillet radii, wall thickness optimization, and feature orientation to reduce tool wear and machining time. Programming and simulation were completed using CAD and CAM systems such as SolidWorks, UG, and CATIA.

Supported drawing formats included STEP, DWG, DXF, IGS, STL, and PDF. Free samples were provided during the validation stage to support assembly testing and on-vehicle evaluation.

Broader Applications of Automotive Titanium Machining

While this case focused on performance automotive components, the machining strategies developed are applicable across multiple industries. Similar CNC titanium machining approaches are used in motorcycle racing, energy systems, robotics, and advanced industrial equipment.

Experience gained from automotive projects strengthens process flexibility and efficiency, allowing titanium machining companies to serve diverse markets with varying volume and performance requirements.

Conclusion

This automotive titanium CNC machining case demonstrates how advanced machining strategies, high speed machining titanium techniques, and precise quality control can support the production of high-performance automotive components. By addressing the machinability challenges of titanium alloys and optimizing process efficiency, manufacturers can deliver reliable, lightweight, and durable machined titanium parts for demanding automotive applications.

Through CNC titanium machining, titanium milling, titanium turning, and waterjet titanium cutting, performance automotive manufacturers gain access to material advantages that directly translate into improved vehicle performance and reliability.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.