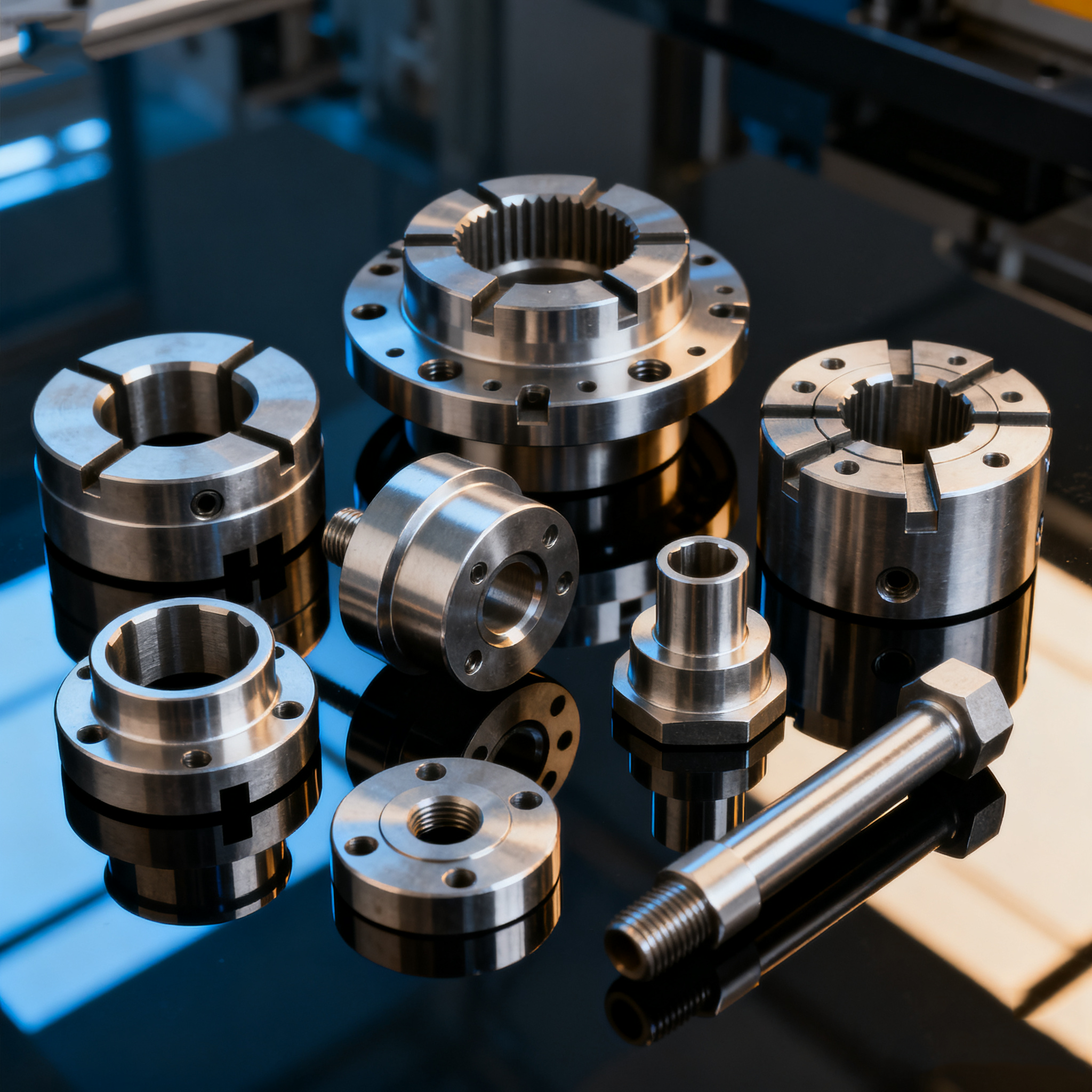

Titanium CNC Turning Parts

Titanium Milling and Waterjet Cutting for Medical Device Components

- Product ID: Titanium CNC Turning Parts

- Tel: +8618998453346

- WhatsApp: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2024-09-01 00:15

- Price: 0

Low thermal conductivity leading to heat buildup

Work hardening tendencies

Potential for tool wear during fine feature machining

Precise cutting of thin sheets and plates

Creation of near-net-shape blanks

Complex cutouts without heat-affected zones

Milling for precise contours, pockets, and flanges

Drilling and countersinking for assembly points

Finishing of mounting and mating surfaces

Titanium waterjet cutting to produce near-net-shape blanks

CNC titanium milling to finalize functional surfaces

Post-machining inspection and deburring

Optimize waterjet cutting paths for thin and complex parts

Plan CNC milling sequences for accuracy and surface finish

Validate prototypes before full-scale production

Orthopedic implants and plates

Surgical instruments

Precision medical device components

Background: Precision Medical Components

Medical devices require titanium components that are lightweight, biocompatible, and corrosion-resistant. These parts often feature intricate geometries, thin walls, and complex contours. Combining titanium milling with waterjet cutting allows manufacturers to achieve near-net shapes with high precision and minimal material waste.

In this project, the customer required surgical implants, orthopedic plates, and other medical components. Waterjet cutting was used to cut raw titanium blanks accurately, followed by CNC titanium milling for functional surfaces and assembly features.

Material Selection and Machinability Considerations

Titanium alloys suitable for medical applications provide high strength, low density, and biocompatibility. Machinability of titanium alloys is challenging due to:

Waterjet cutting titanium produced flat, distortion-free blanks, minimizing stress and preserving material properties for subsequent milling operations.

Titanium Waterjet Cutting Process

Waterjet cutting titanium enabled:

Jet cutting speed for titanium was optimized based on plate thickness, ensuring clean edges for milling operations.

CNC Titanium Milling for Functional Features

CNC titanium milling operations included:

High-speed machining titanium parameters were carefully selected to ensure consistent surface quality and dimensional accuracy.

Dimensional Accuracy and Surface Finish

All critical features were held within ±0.01 mm tolerance. Surface finish was optimized for medical standards, including smoothness for tissue contact and implant interfaces. CMM inspection and visual verification ensured compliance with quality requirements.

Integration Workflow

The workflow combined waterjet cutting and milling for maximum efficiency:

This integrated approach minimized material waste and reduced machining time while maintaining high precision.

OEM Support and Engineering Collaboration

The project followed an OEM model. Engineering teams collaborated to:

Supported drawing formats included STEP, DWG, DXF, IGS, STL, and PDF. CAD/CAM tools such as SolidWorks, UG, and CATIA were used.

Applications in Medical Devices

Titanium waterjet cutting combined with CNC milling is widely applied for:

This approach ensures biocompatibility, dimensional accuracy, and high-quality surface finishes required in medical applications.

Conclusion

This case demonstrates how titanium milling integrated with waterjet cutting enables the production of precise medical device components. Optimized jet cutting speed, CNC milling parameters, and inspection protocols ensure high-quality, reliable, and biocompatible machined titanium parts.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp: +8618998453346

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Room 302, Building D, COFCO Gonghua Project, Zone 20, Honglang Community, Xin'an Street, Bao'an District, Shenzhen City.